How It Works

Glass beads mixed with heated water and air are forced at high pressure to produce a soft finish. This none aggressive process and will not remove any material from the surface of the component. The water acts as a lubricant and cushions the impact as it strikes the surface. This produces a peening and burnishing effect giving the surface an even satin polished effect.

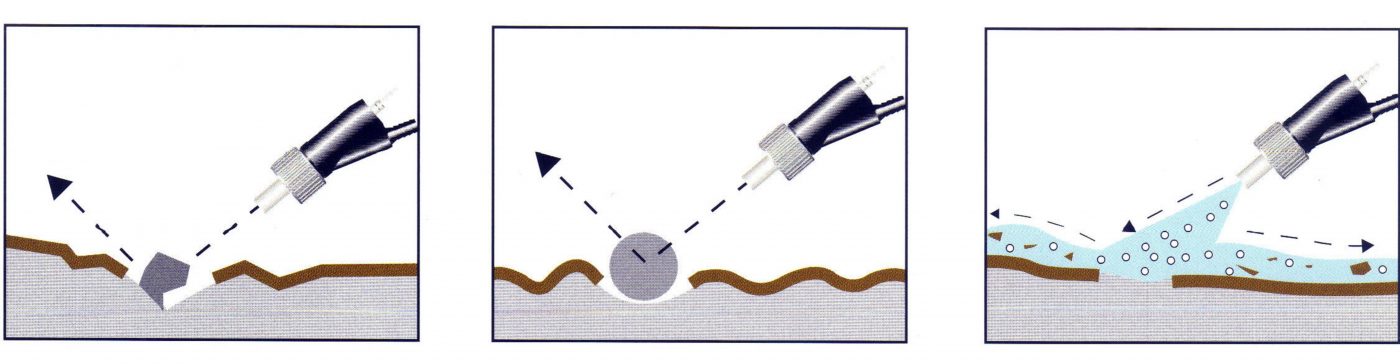

Dry Grit Blasting

Dry Bead Blasting

Wet Vapour Blasting

The aggressiveness of dry grit and bead blasting shown in the first two illustrations demonstrates the severe 90 degree ricochet that occurs smashing the media and tearing at the surface of the component. Slightly lessor with dry bead due to the media shape making a smother finish.

With vapour blasting the ricochet of the media is reduced to the cushioning of the water, the angle of the media is changed producing a lapping effect traveling across the surface giving an even satin polished effect. With no loss of material and keeping dimensional stability compared to the other two processes. Vapour blasting is easy to keep clean and with its none-reflective surface makes it an ideal finish for many applications.

The process is good on Aluminium, Brass, Bronze, Copper, Magnesium, Stainless Steel and Titanium and most none ferrous materials.